50KW Off Board Charger Transformer with Embedded LLC Resonant Choke

At the heart of Premo’s innovation lies a compact 50KW Off Board Charger Transformer with LLC Resonant Choke set meticulously engineered to meet the demanding power requirements of modern EVs. Housed within a sleek 300 x 174 x 100 mm aluminum casing, this high-performance transformer boasts remarkable efficiency, delivering power with over 99% efficiency. This exceptional efficiency ensures minimal power loss, reducing overall energy consumption and promoting sustainable charging practices.

The BCBM-50KW-001 50KW Off Board Charger Transformer with LLC Resonant Choke set incorporates advanced design elements to optimize performance and address the critical issue of thermal management. A key feature is the embedding of a resonant choke for LLC (LCLC) topology, allowing for efficient energy transfer and reduced switching losses.

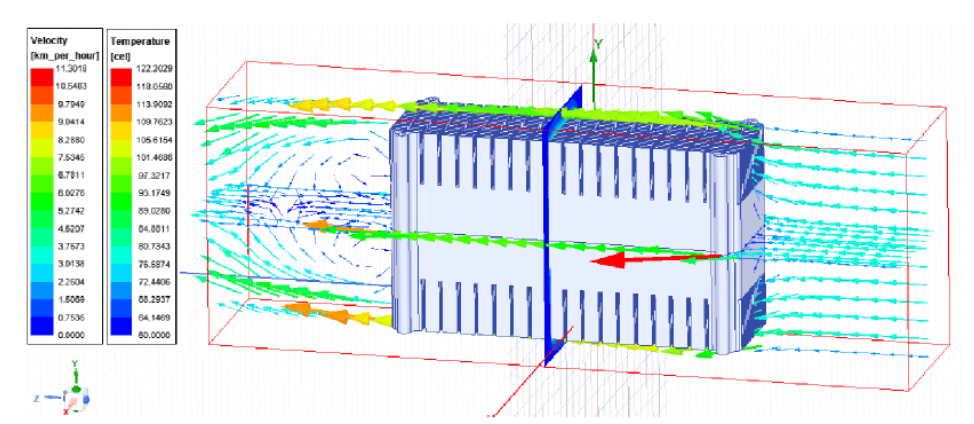

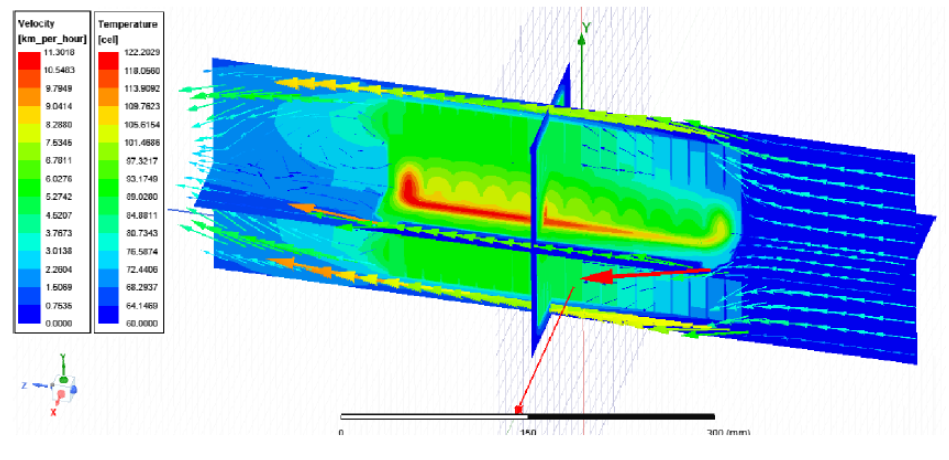

To facilitate effective heat dissipation, the part is designed with the new Premo patented technology of internal fins that work together with Coolmag thermo-conductive resin —a material specifically chosen for its superior heat transfer properties.

The utilization of triple Insulated Litz wires ensures excellent thermal dissipation while accommodating thermal expansion and contraction. This soft and flexible insulation mitigates the risk of damage caused by temperature fluctuations, thus ensuring the reliable performance and durability of the transformer set. Furthermore, the distributed gap multicore design, combined with the utilization of MnZn Ferrite Cores, enhances the overall protection and thermal stability of the transformer.

The 50KW Off Board Charger Transformer with LLC Resonant Choke Set with an embedded resonant choke for LLC topology represents a significant leap in power electronics for EV chargers. Its compact size, exceptional efficiency exceeding 99%, and advanced thermal management capabilities make it an ideal choice for fast-charging stations catering to the expanding EV market.

Premo is committed to SDGs (United Nations Sustainable Development Goals) and designs, engineers, prototypes, and tests full reliability at its green carbon net positive Innovation Center. PFC modules are thus engineered under sustainability standards that design for the circular economy, considering 0km materials of natural origins, using green energy, and minimizing the content of polymers from fossil fuels as well as recycled ferrites and copper.

If you need more information on this product, download the datasheet here: